Casting

Castings represent a cornerstone of industrial manufacturing, embodying the artful transformation of molten metal into intricate shapes through precision casting processes. These processes offer unparalleled versatility and efficiency, enabling the creation of complex components with meticulous detail and exceptional mechanical properties. From aerospace to automotive, castings serve as the backbone of numerous industries, underpinning innovation, durability, and reliability in a vast array of applications.

Sand Casting

Sand casting stands out as the preferred method for producing large-scale components, offering a vast selection of metal alloys and accommodating various part sizes efficiently. With minimal setup costs and customizable mold adjustments, it ensures cost-effectiveness without compromising quality. Embraced across diverse industries, from aerospace to automotive, sand casting exemplifies innovative metal fabrication, enabling the realization of ambitious engineering designs with unparalleled versatility and affordability.

Materials

1. Ferrous Metals:

- Steel

- Cast Iron (Grey, ductile & malleable iron)

2. Non-ferrous Metals:

- Aluminium

- Copper

- Brass

- Bronze

- Zinc

- Nickel

- Titanium

Applications

- Engine Blocks

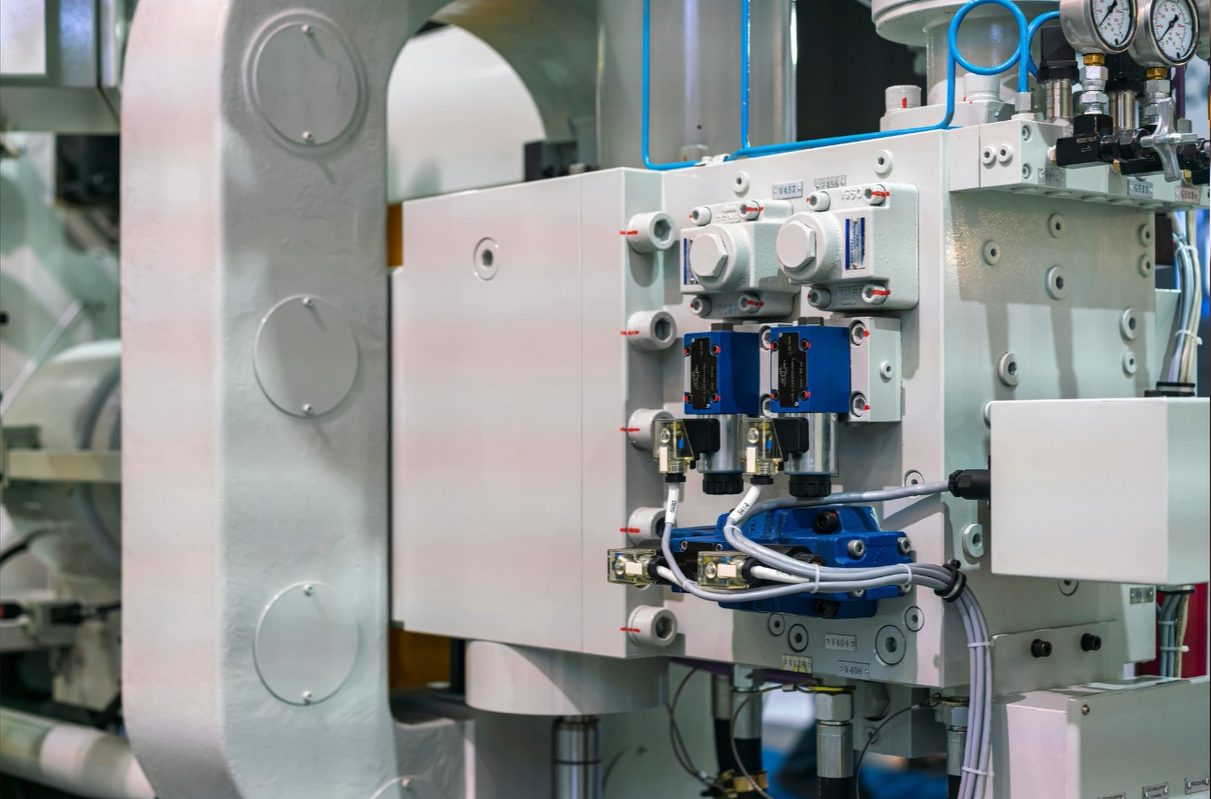

- Valve products

- Locomotive parts

- Pump housings

- Wind turbine products

- Industrial equipment

“ Where versatility meets affordability, shaping ambitious engineering dreams into reality ”

- Sand casting, the go-to for large-scale components, boasts a wide alloy selection and efficient part sizing. Its cost-effectiveness and mold flexibility redefine quality standards.

- With minimal setup costs and mold adjustments, sand casting offers affordability without sacrificing quality. Embraced by industries from aerospace to automotive, it fuels innovation in metal fabrication.

- Sand casting's versatility and affordability make it indispensable for ambitious engineering designs. From intricate aerospace components to robust automotive parts, it delivers unmatched results.

- Join global industries leveraging sand casting's benefits: versatility, affordability, and impeccable quality. Elevate your production standards with a trusted method embraced worldwide.