What are UFIBER Advanced Fiber Brushes?

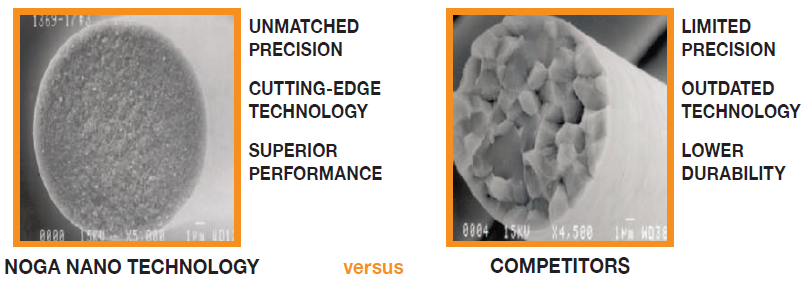

UFIBER Advanced Fiber Brushes are innovative polishing tools designed using nano-technology for superior performance.

They are ideal for surface finishing, deburring, and polishing applications on a variety of materials, including metals,

composites, and hardened surfaces.

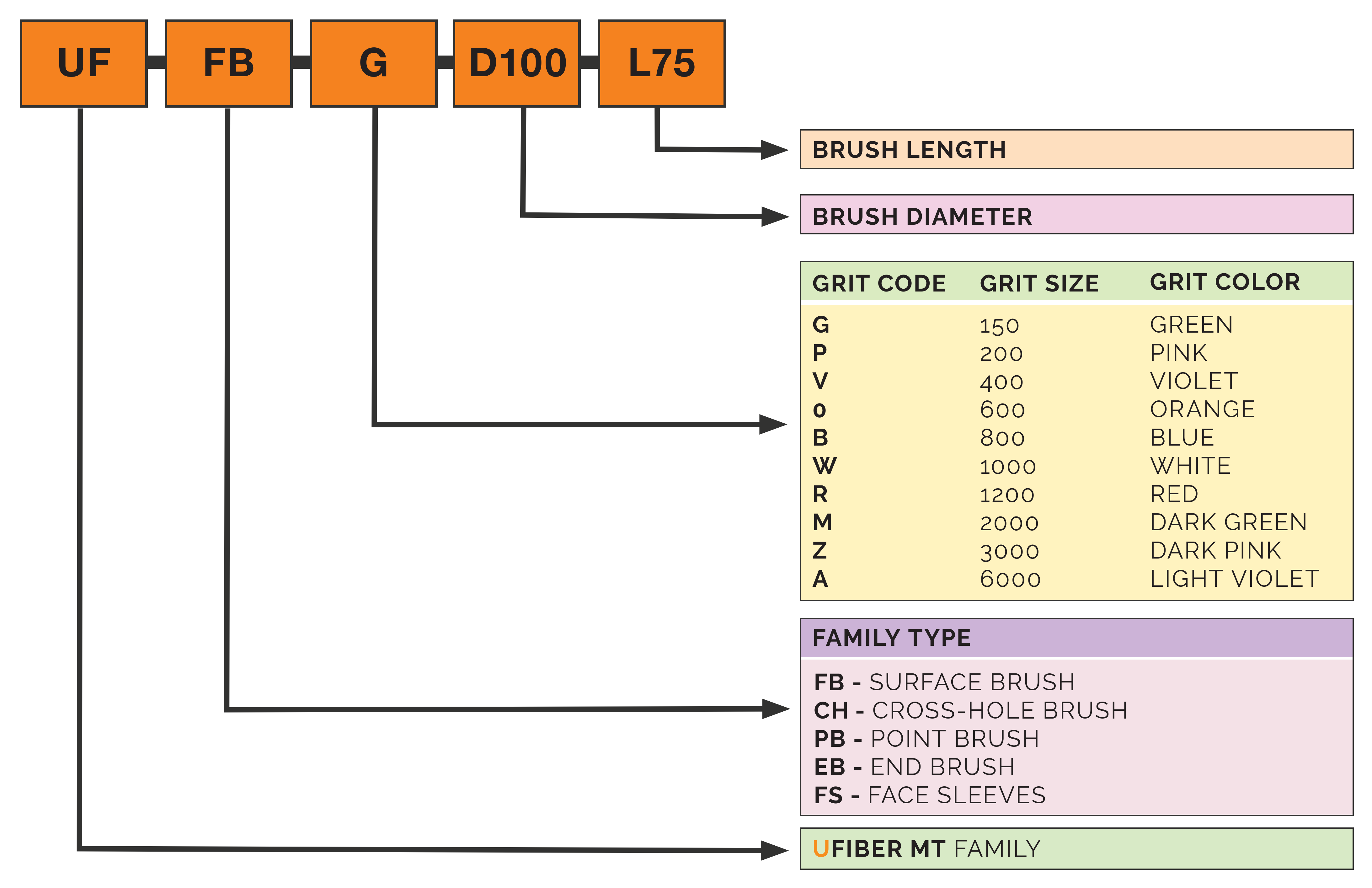

What types of UFIBER brushes are available?

UFIBER offers a range of brush types tailored for different applications:

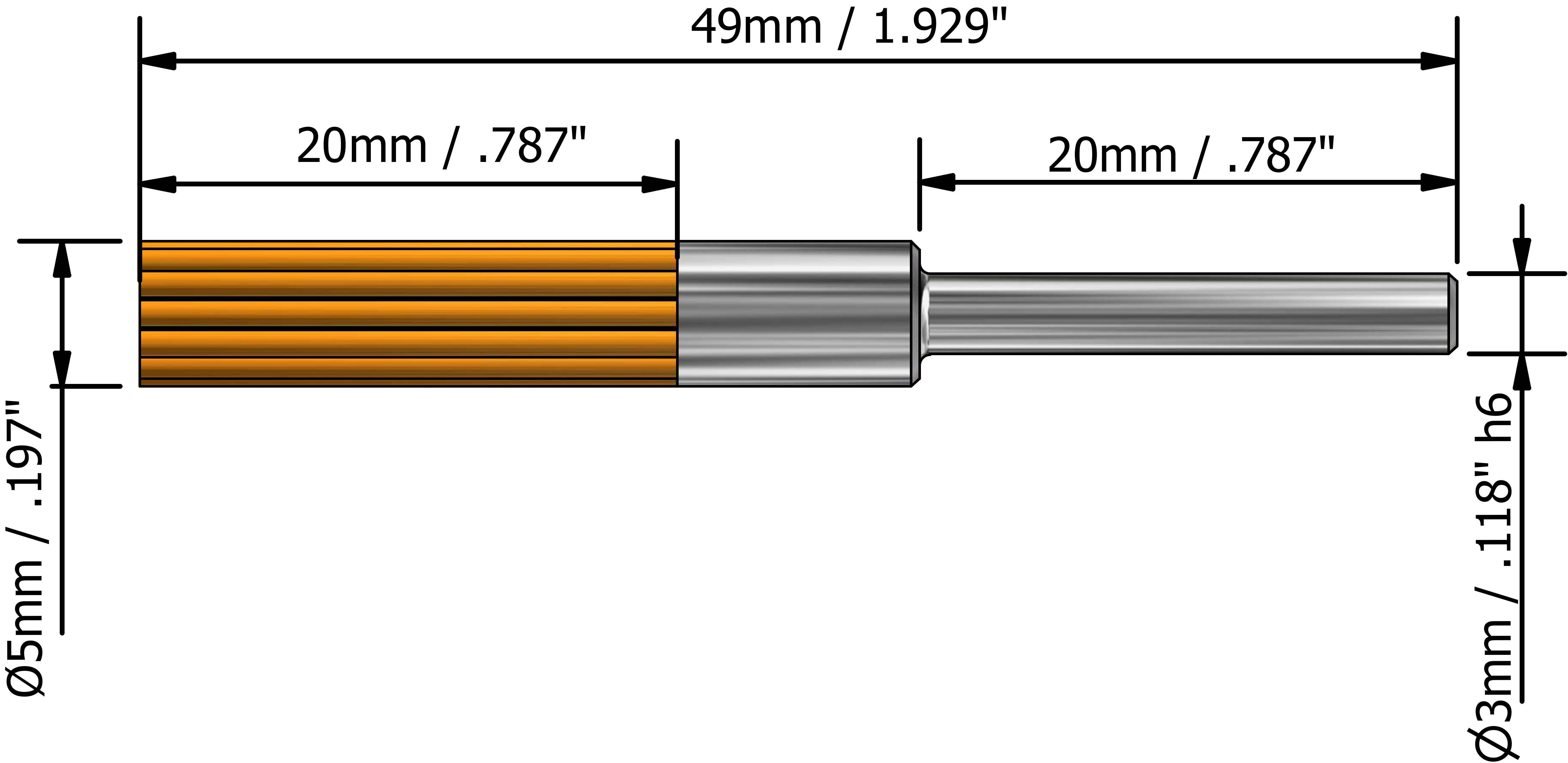

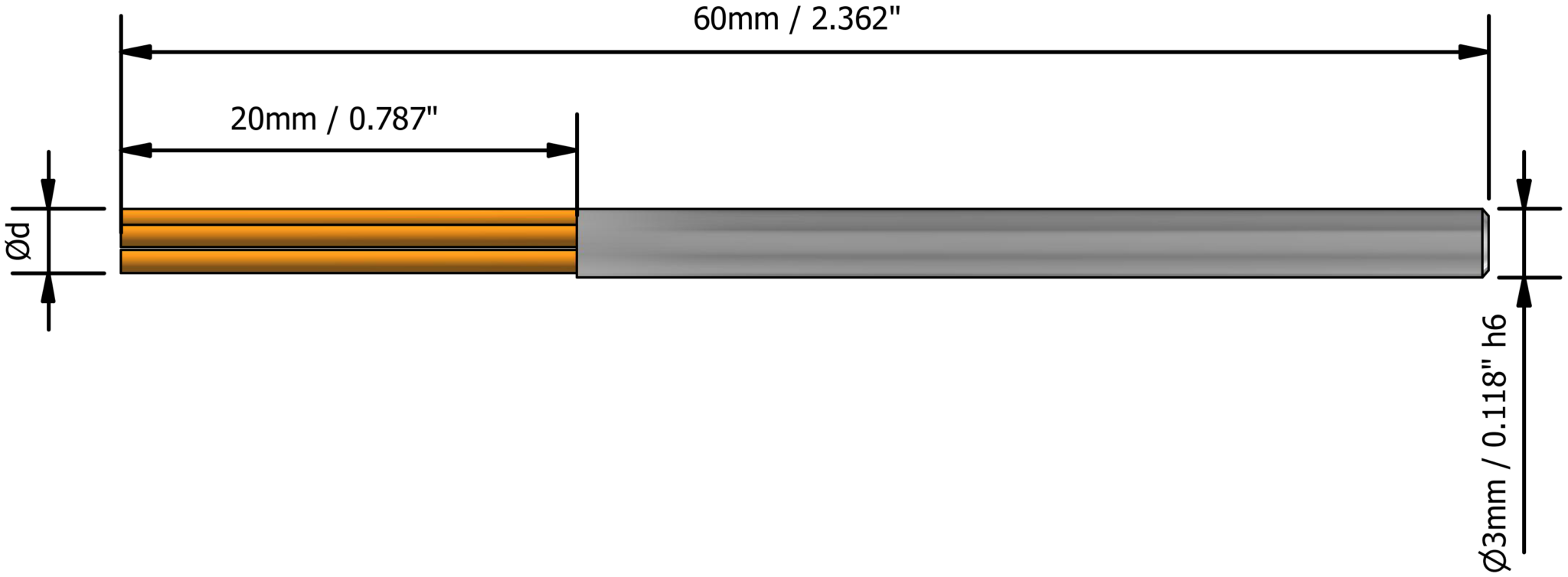

- Surface Type Brushes:For flat surface polishing.

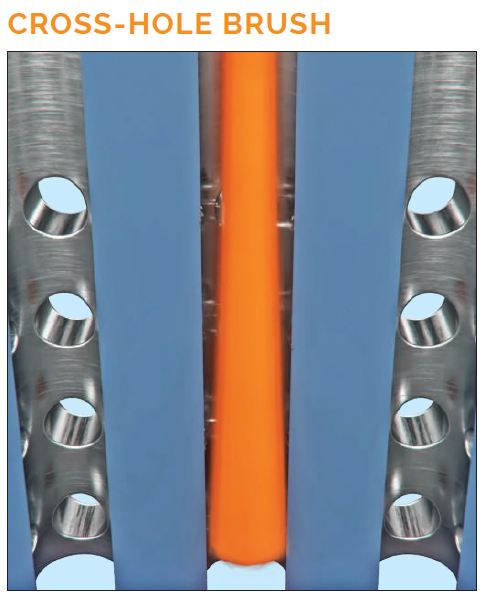

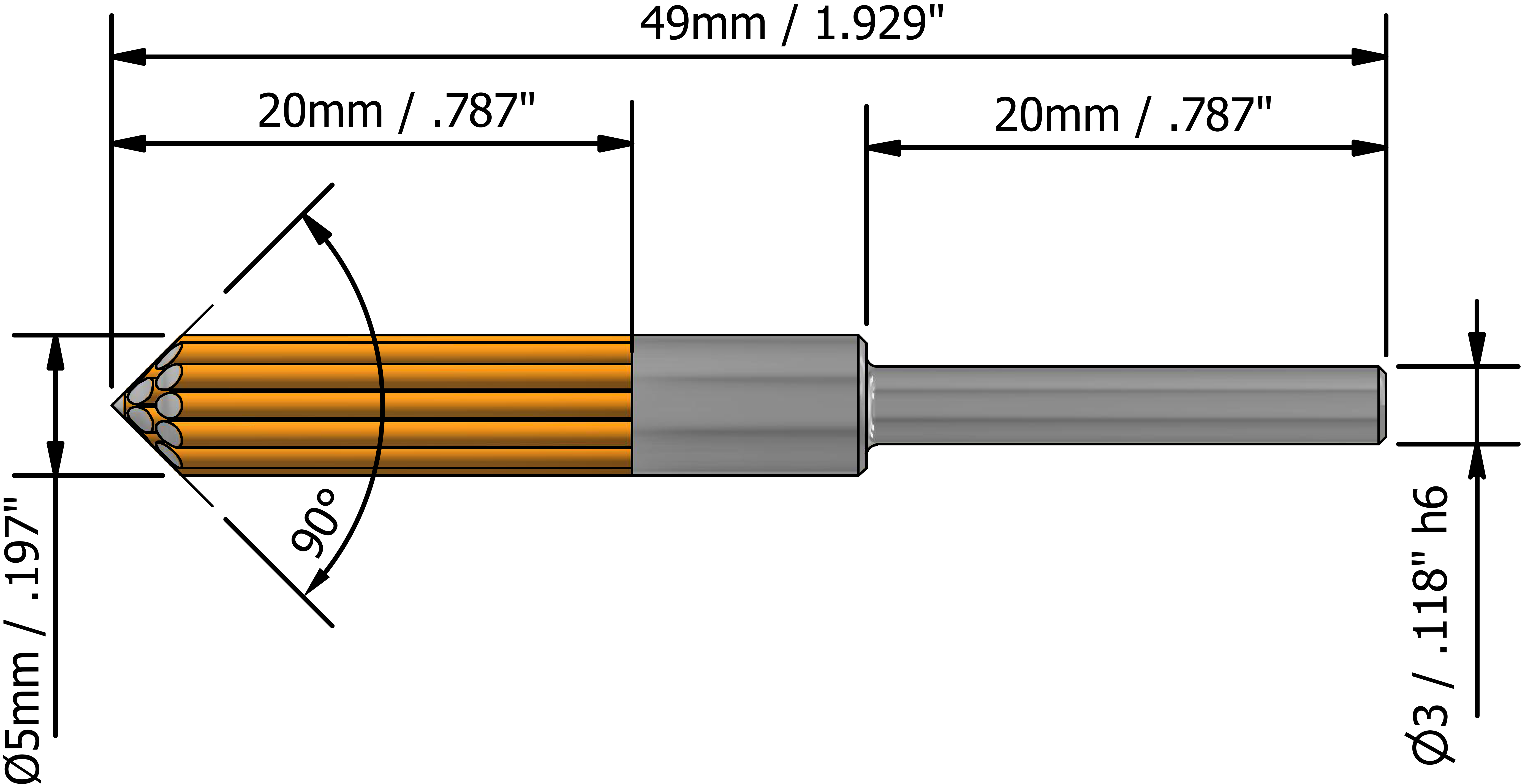

- Cross-Hole Type Brushes: Ideal for deburring and polishing inner diameters of cross-holes.

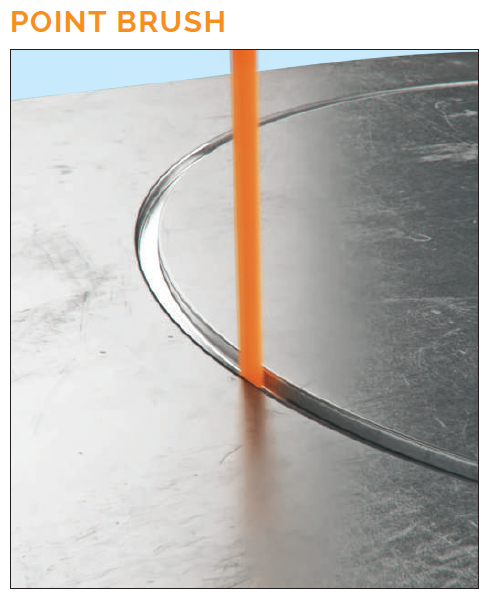

- Point Type Brushes: Suitable for small point polishing tasks.

- End Type Brushes: Designed for precise end-face polishing.

What materials can UFIBER brushes be used on?

UFIBER brushes are compatible with a wide range of materials, including:

- Composite materials (FRP)

- Copper and aluminum

- Stainless steel, carbon steels, and hardened materials

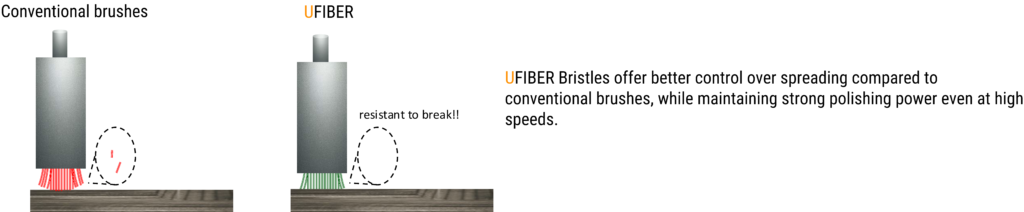

How do UFIBER brushes perform compared to traditional brushes?

UFIBER brushes offer superior wear resistance, consistent surface roughness control, and longer lifespan compared to

traditional abrasive brushes. Their nano-technology design ensures efficient and precise material removal.

Are UFIBER brushes suitable for automated processes?

Yes, UFIBER brushes are compatible with CNC machines and robot arms, making them ideal for automated manufacturing

environments. They provide reliable and consistent performance in automated deburring and polishing tasks.

Can UFIBER brushes be used with coolant?

Yes, UFIBER brushes can be used with or without coolant. Using coolant can enhance tool life and improve the surface

finish.

How should I select the right UFIBER brush for my application?

Choosing the right UFIBER brush depends on the material, the shape of the workpiece, and the desired surface finish.

Consult our product selection guide or contact our technical support team for personalized recommendations.

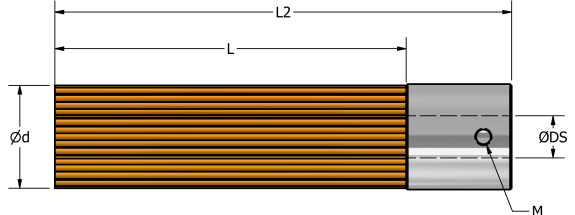

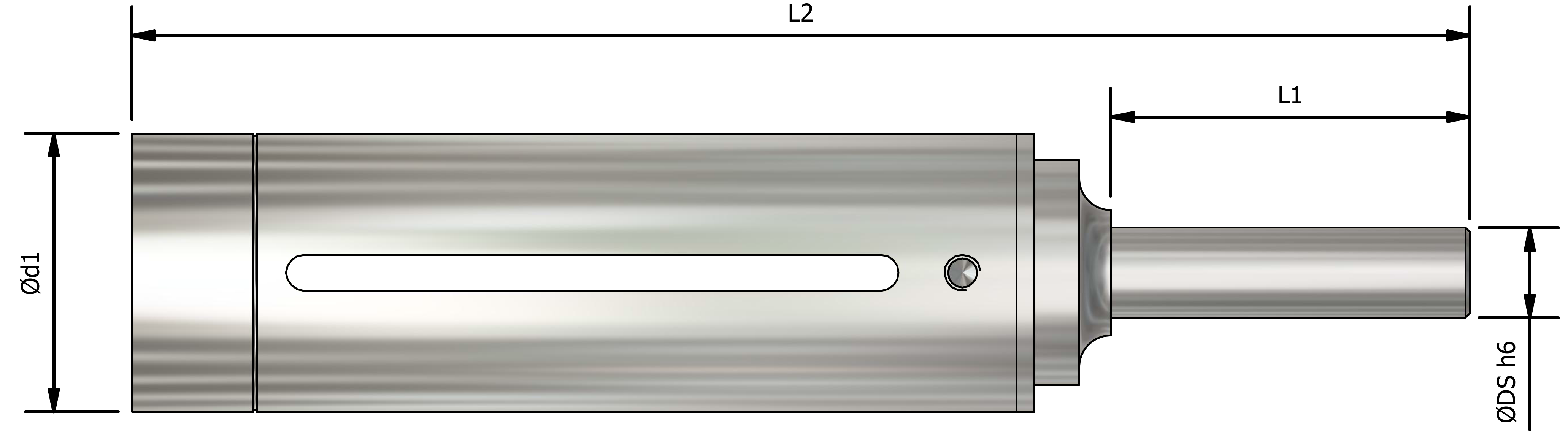

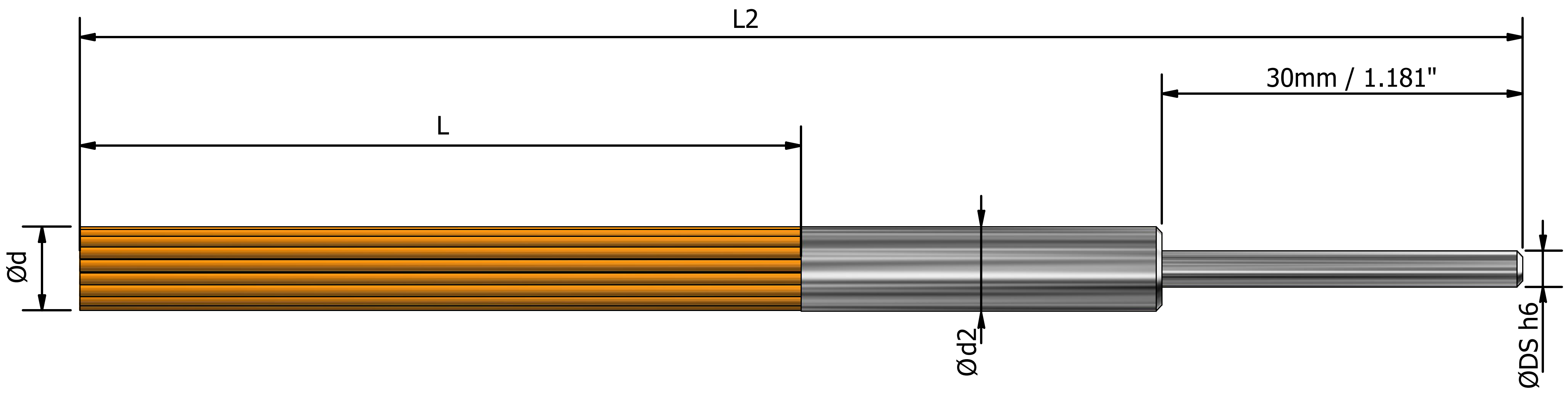

How do I install UFIBER brushes?

UFIBER brushes are easy to install. Ensure the correct brush size and type are selected, then mount the brush securely

on your machine following the manufacturer’s guidelines. Always check that the brush is properly centered before

operation.

What safety precautions should be taken when using UFIBER brushes?

Always wear appropriate personal protective equipment, such as safety glasses and gloves, when operating UFIBER brushes.

Ensure that the machine guard is in place, and operate the brush within the recommended speed limits.

How do I maintain and store UFIBER brushes?

Store UFIBER brushes in a dry, cool environment away from direct sunlight. Inspect brushes regularly for wear or damage,

and replace them as needed to maintain optimal performance.