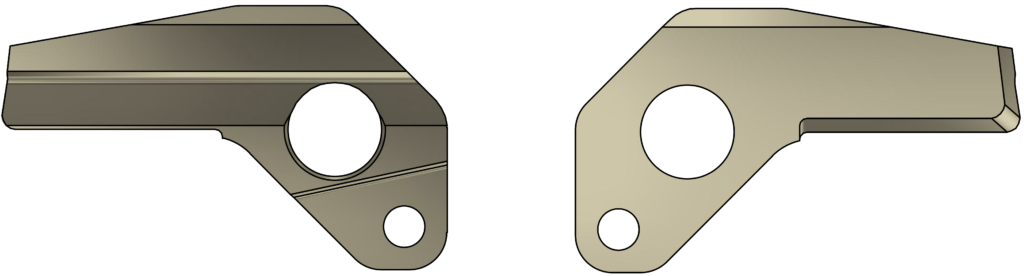

UBACK AND USPOT INSERTS

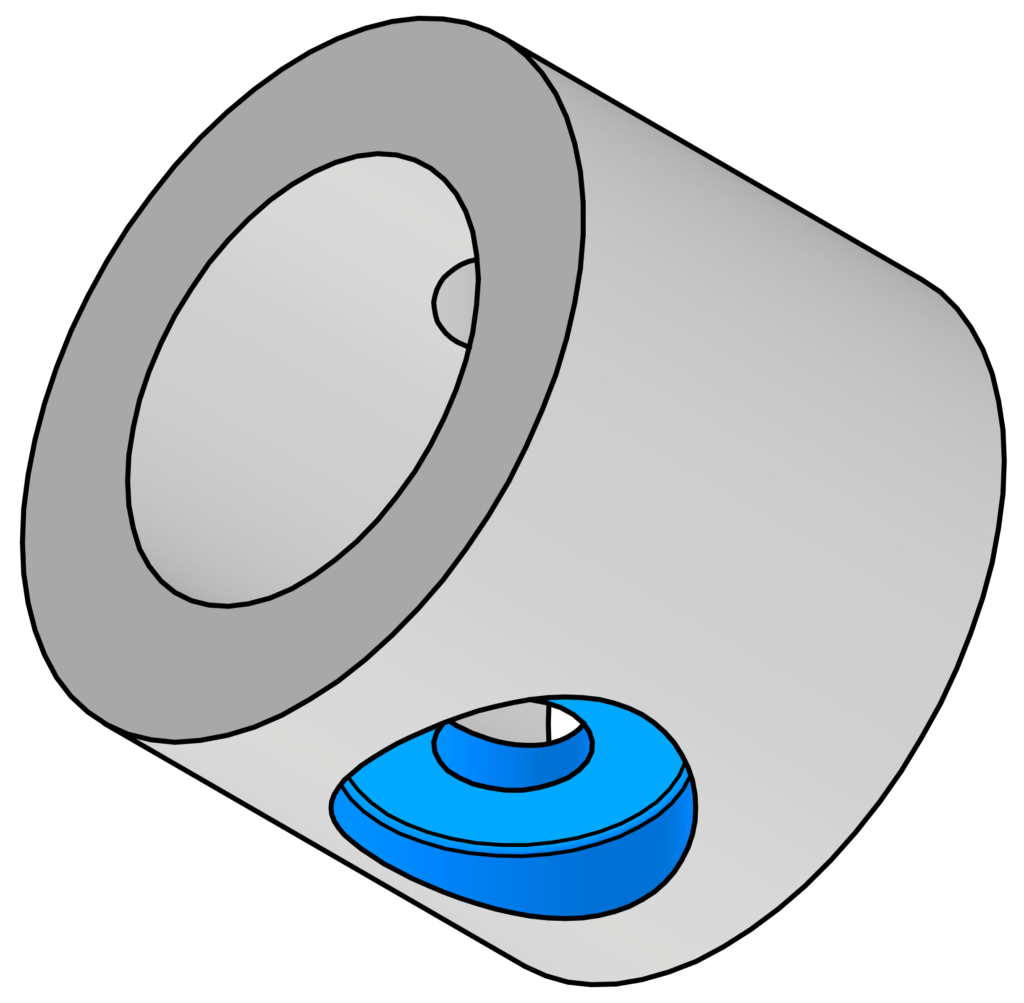

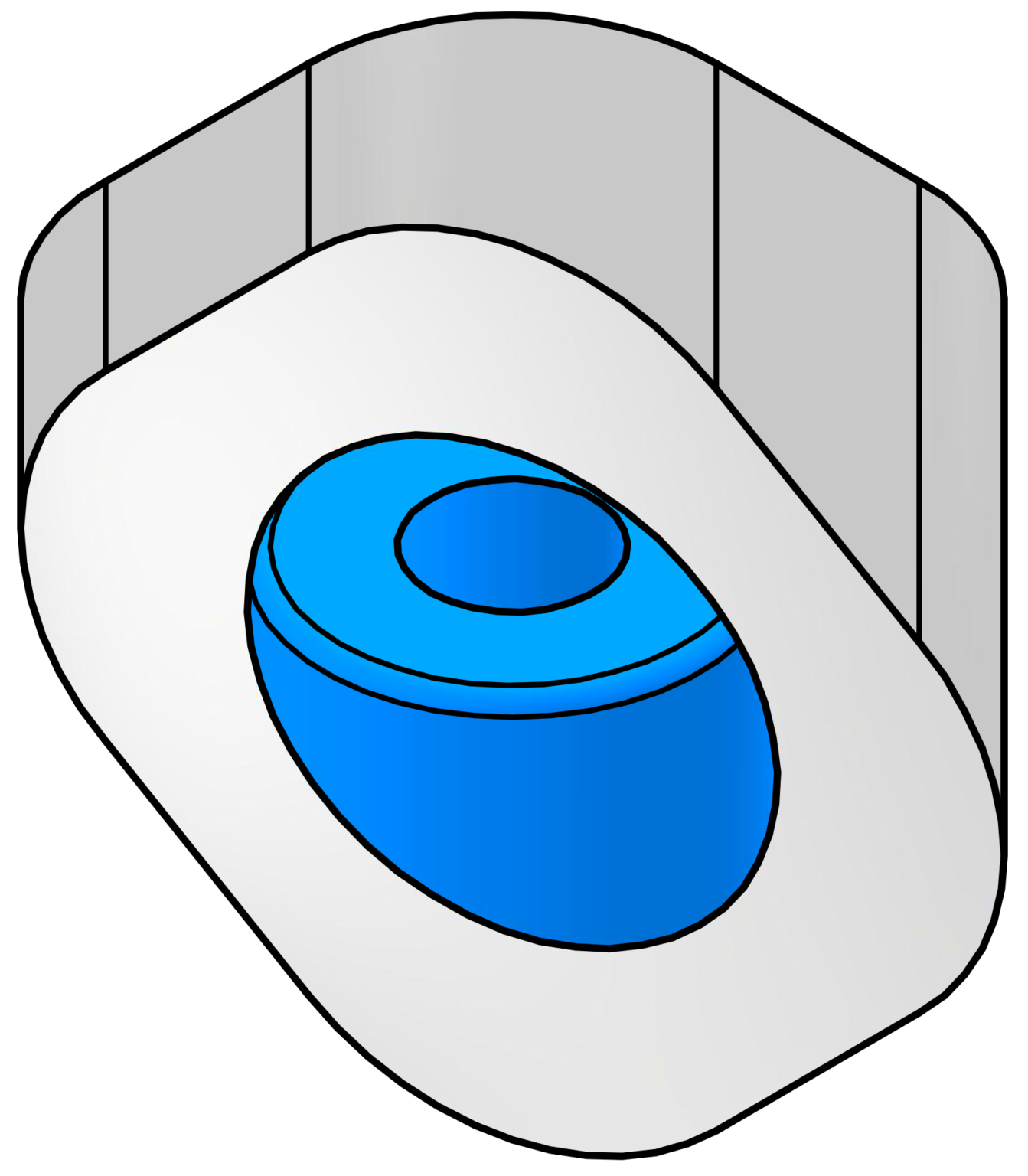

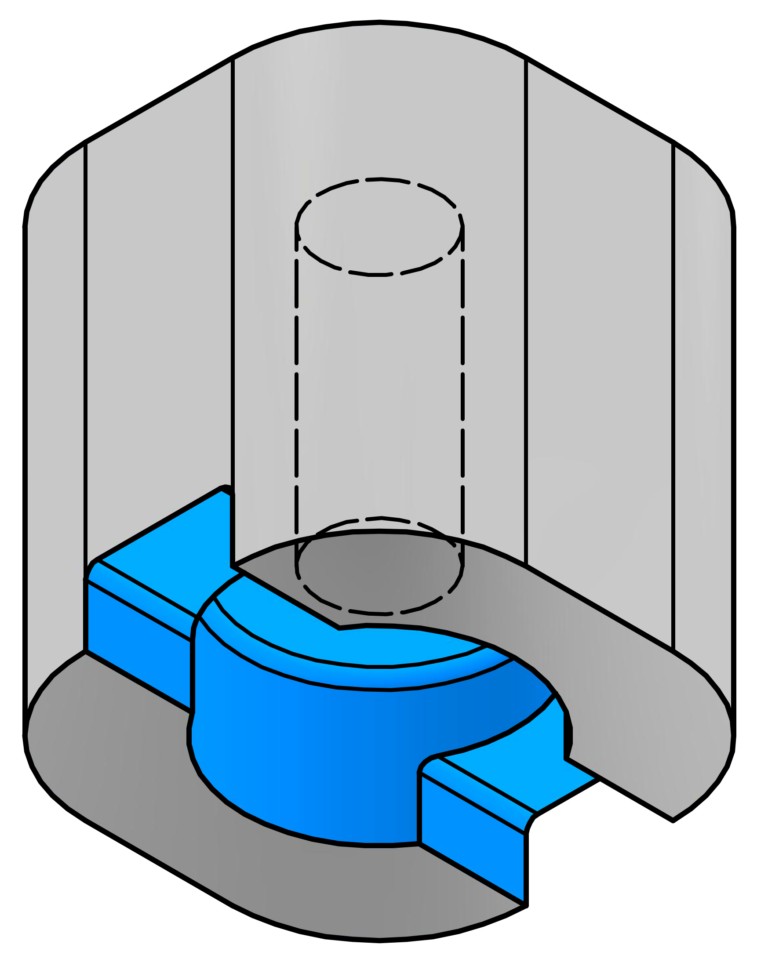

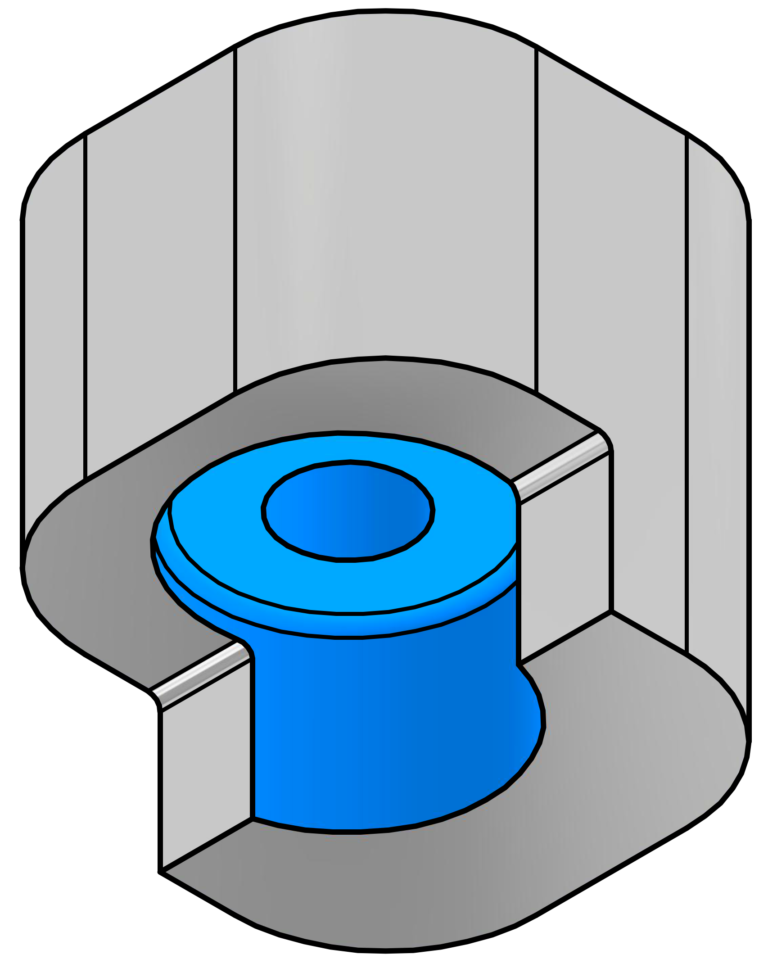

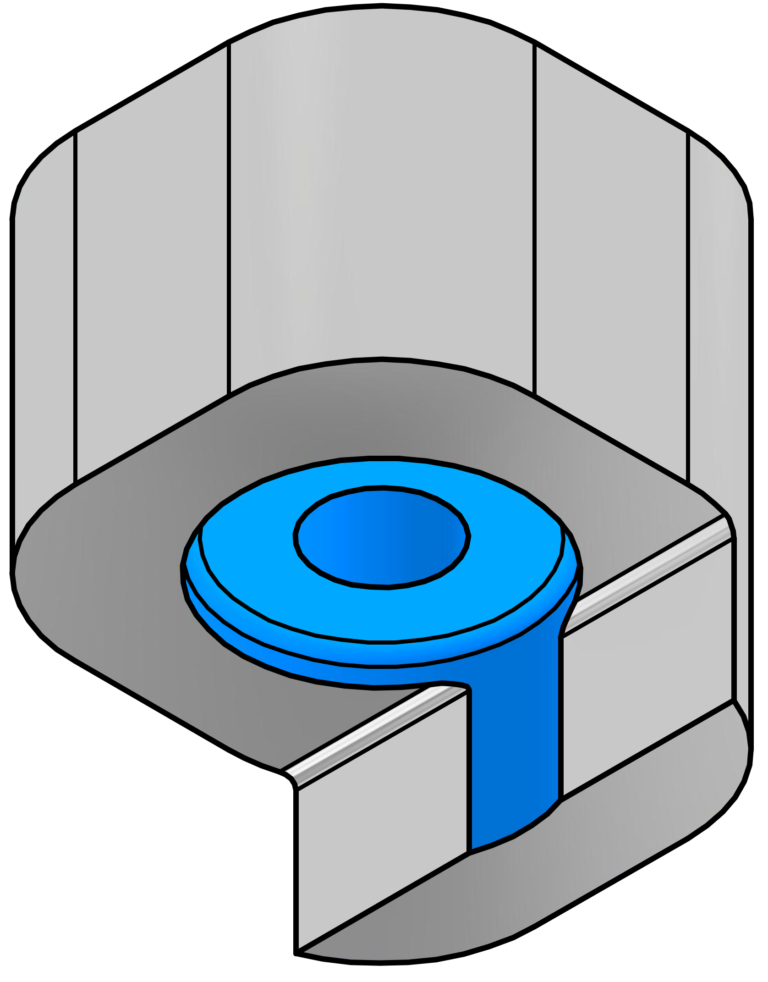

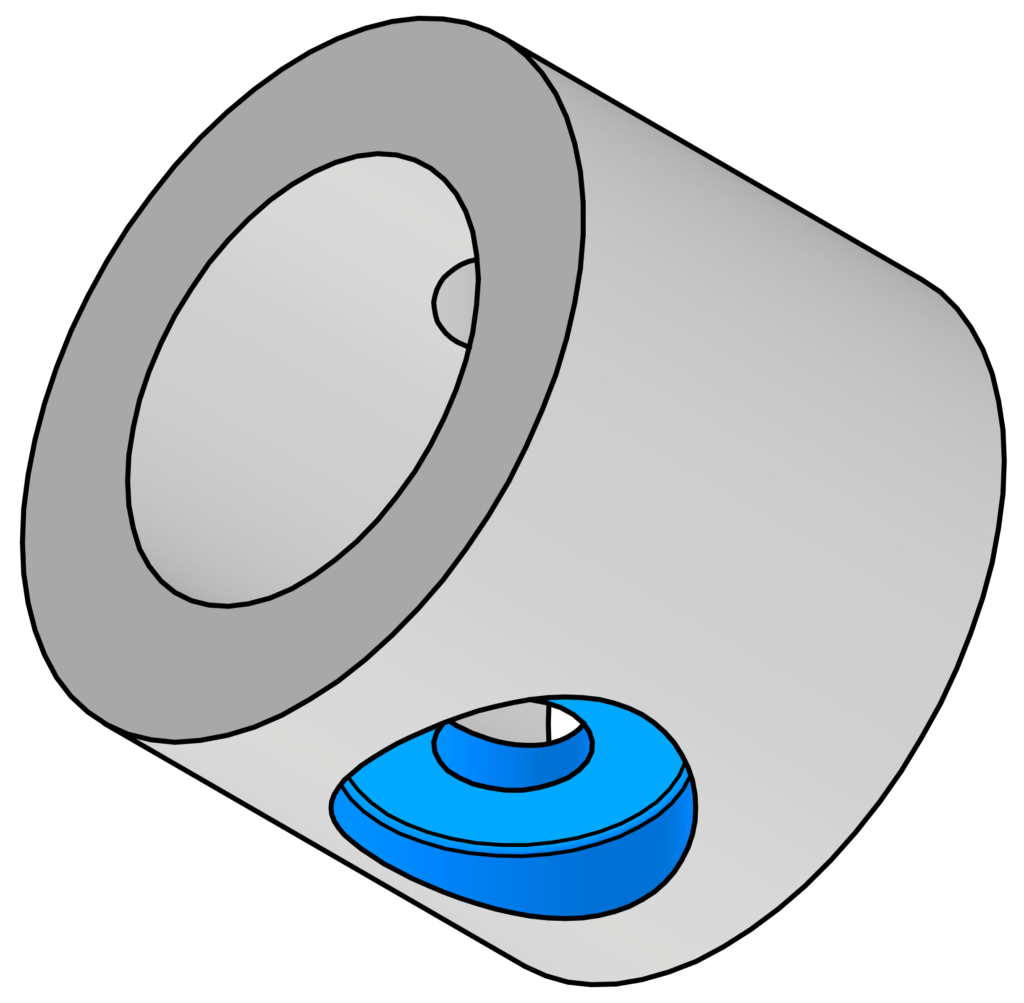

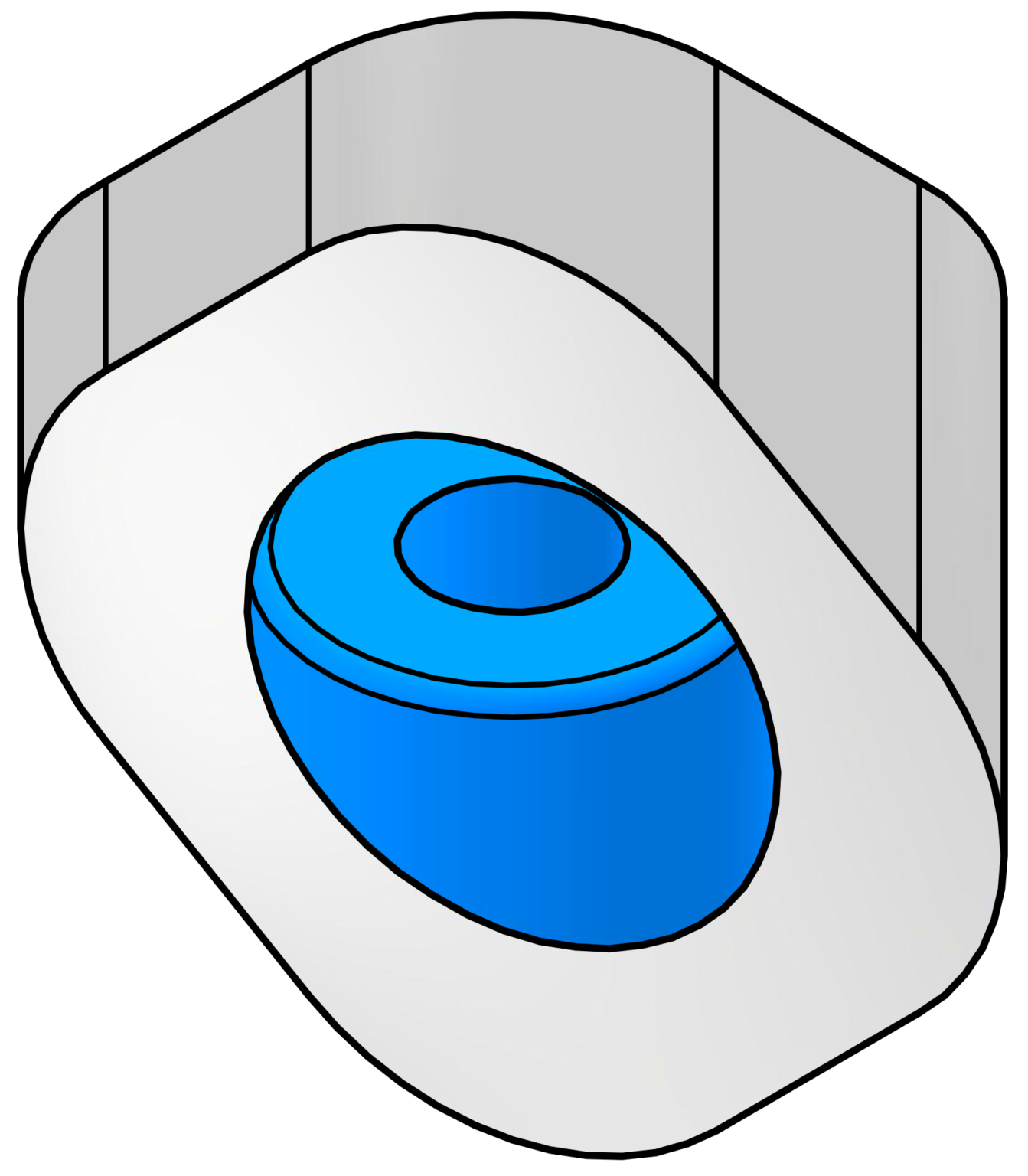

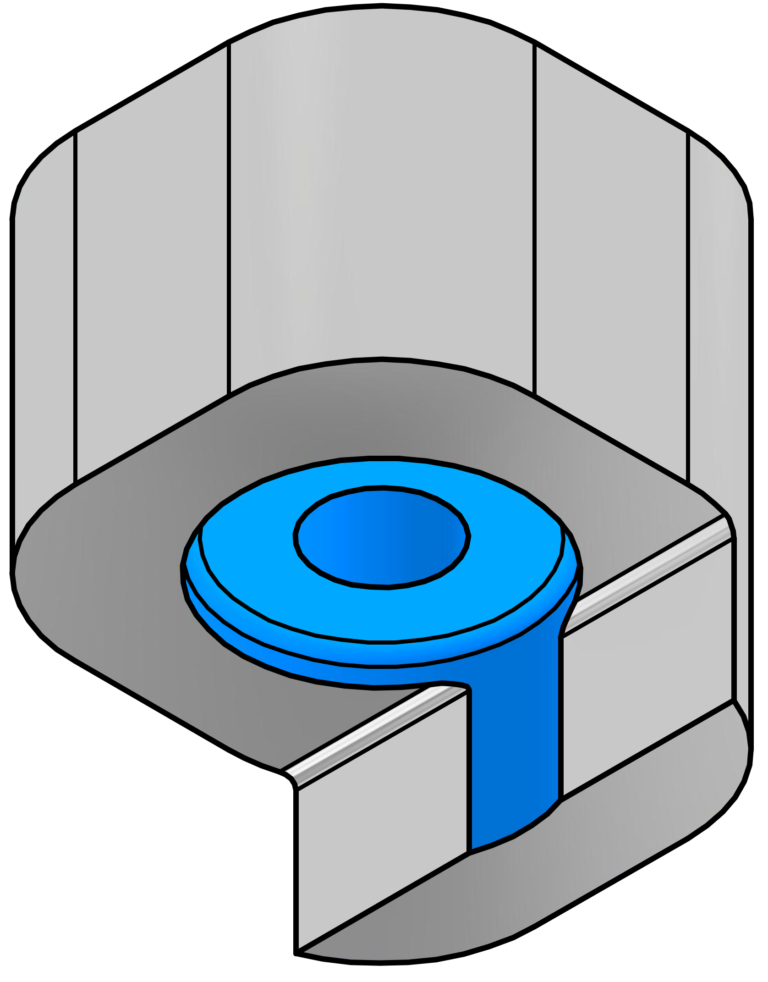

The Ultimate Back line brings together the innovative UX tool-holders and USPOT/UCHAMF inserts to redefine machining precision. Featuring a patented hydraulic mechanism that ingeniously uses the machine’s coolant liquid, this system delivers exceptional control over insert movement. The result? Unparalleled accuracy, repeatability, and streamlined operations for back counterboring, back countersinking, and back spot-facing tasks.

With its advanced engineering, Ultimate Back eliminates the need for workpiece rotation, effortlessly performing operations in a single pass while significantly boosting productivity and efficiency.

The Ultimate Back system combines the precision ofUX tool-holders with the versatUility of USPOT and UCHAMF inserts to deliver unparalleled performance. Its innovative design optimizes machining processes, reduces cycle times, and achieves flawless results in high-demand industries.

Whether you’re working in aerospace, automotive, medical, or electronics sectors, Ultimate Back is the ultimate choice for back spot-facing, back counterboring, and back countersinking operations.

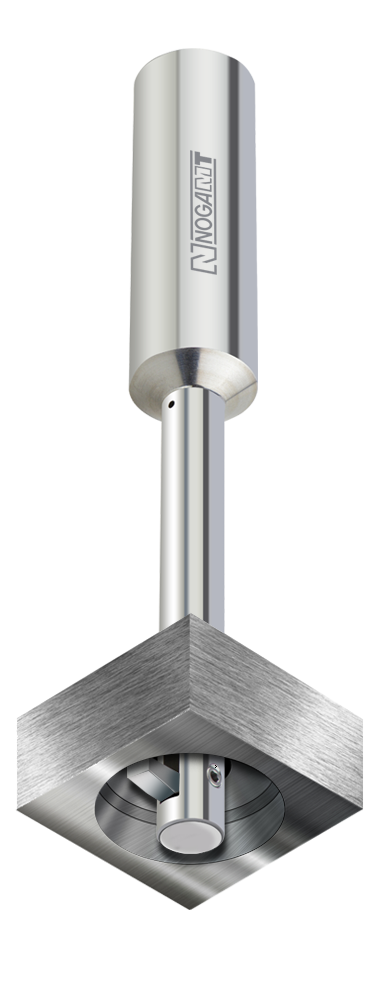

When you see this logo on our tools, you can trust that you’re holding a product built for excellence. DURASHIELD represents NOGA MT’s premium line of tool-holders, engineered to excel in the most demanding environments. Delivering exceptional performance, extended tool life, and unmatched reliability, DURASHIELD tool-holders feature advanced corrosion resistance and superior structural integrity. They set a new benchmark for strength, durability, and precision, redefining industry standards.

The NOGA MT DURASHIELD family of tool-holders undergoes a passivation process to enhance corrosion resistance. This process eliminates the need for additional coatings and chemicals, simplifies production, reduces environmental impact, and provides a more eco-friendly corrosion protection solution.

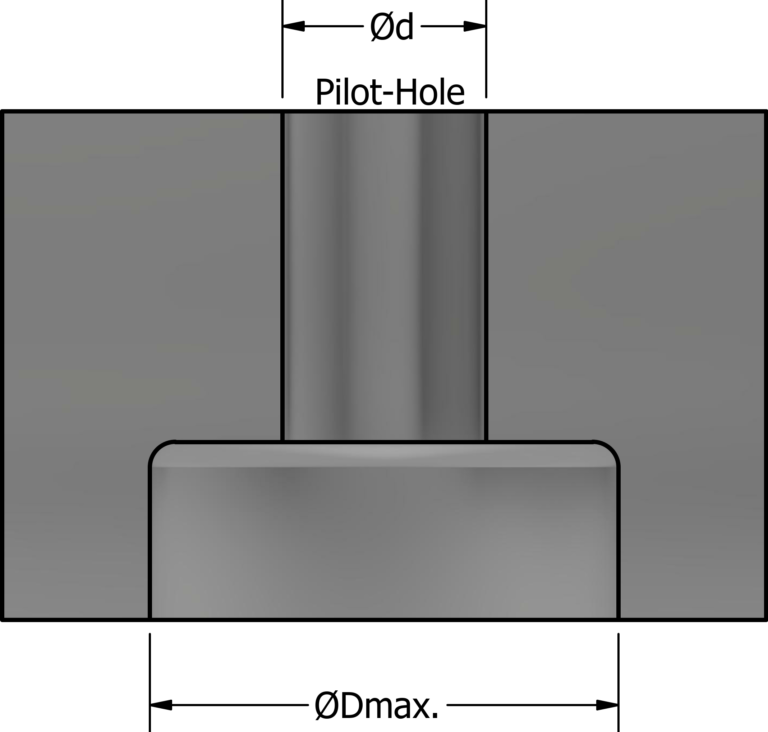

The UBACK line is organized into series or groups, with each series optimized for a specific pilot-hole range:

| Series | Ød Pilot-Hole Range mm / inch |

ØDmax. Counterbore Range mm / inch |

|---|---|---|

| B | 8.0–10.0 /0.315–0.394" |

8.5–20.0 /0.335–0.787" |

| C | 11.0–13.0 /0.433–0.512" |

11.5–28.0 /0.453–1.102" |

| D | 14.0–16.0 /0.551–0.630" |

14.5–34.0 /0.571–1.339" |

| E | 17.0–19.0 /0.669–0.748" |

17.5–40.0 /0.689–1.575" |

| F | 20.0–22.0 /0.787–0.866" |

20.5–43.0 /0.807–1.693" |

| G | 23.0–25.0 /0.906–0.984" |

23.5–46.0 /0.925–1.811" |

The USPOT inserts are offered as semi-standard solutions tailored to meet customer-specific applications.

.png)

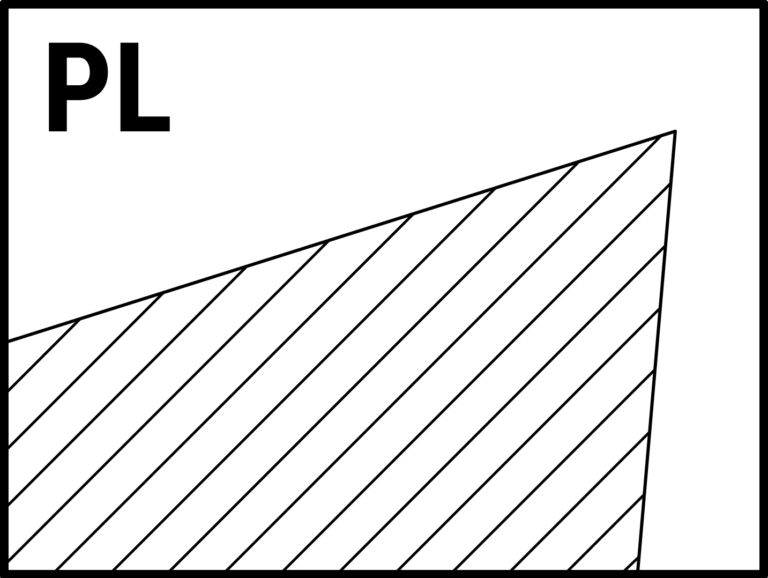

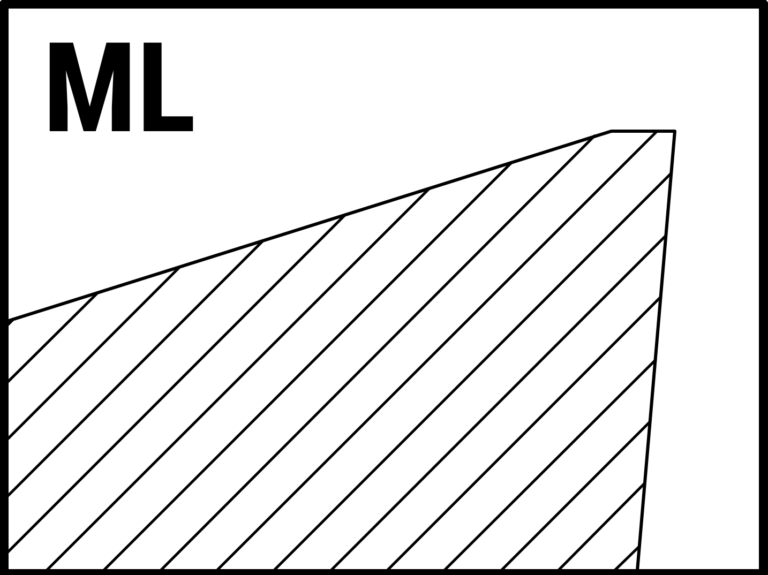

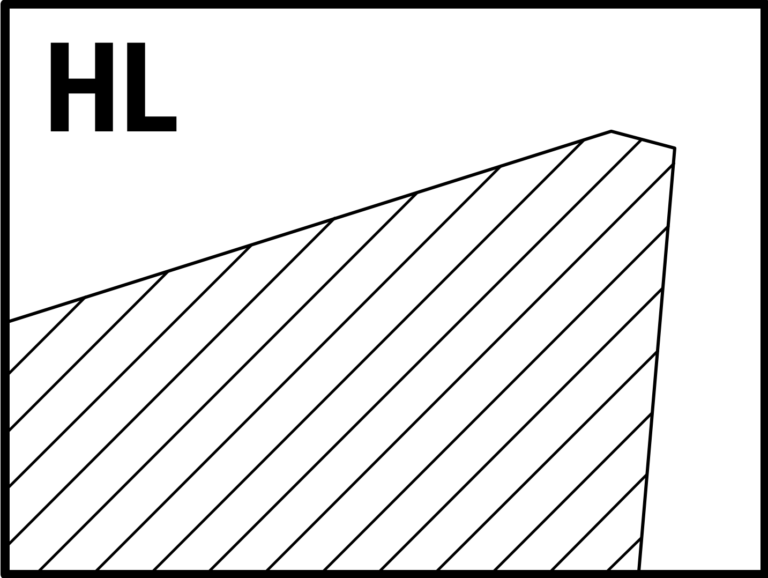

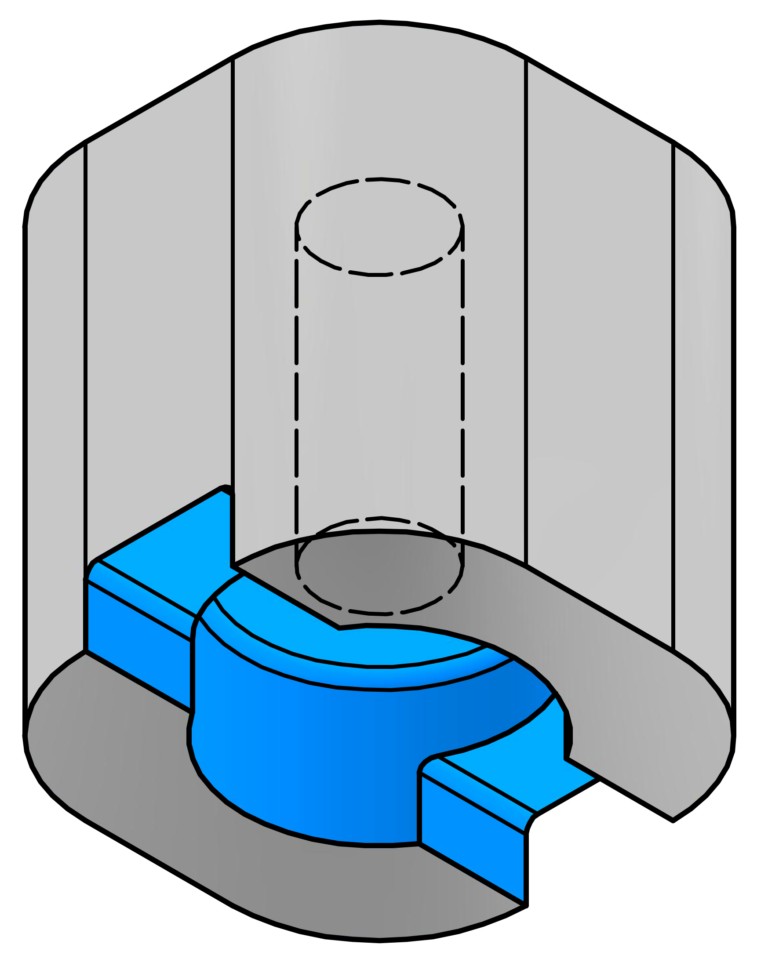

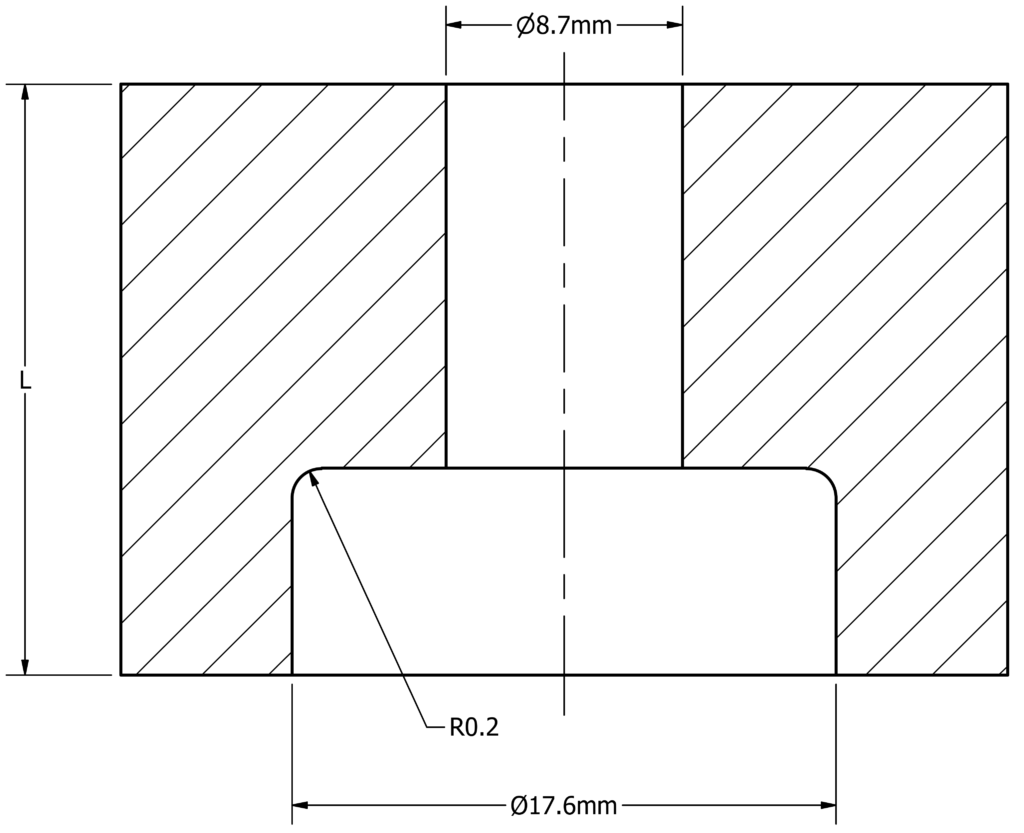

LTB1 – Length To Bottom / RFC – Relief For Cutting / FL – Folding Length

| Ødmin. Pilot Hole |

Tool- Holder SKU |

Tool-Holder Description |

ØDS h6 | FL | RFC | H | L | L1 | LTB1 (1) USPOT |

Weight (gram) |

Insert Clamping Screw M*P*L (mm) |

Series (3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | UX2080 | UX-d080-B-C16-H62-L115 | 16 | 17 | 43 | 62 | 115 | 53 | 8.25 | 69 | UX0005 M2.5×0.35×7B |

B |

| 9 | UX2090 | UX-d090-B-C16-H62-L115 | 16 | 17.8 | 43 | 62 | 115 | 53 | 8.25 | 76 | B | |

| 10 | UX2100 | UX-d100-B-C16-H62-L115 | 16 | 18.4 | 43 | 62 | 115 | 53 | 8.25 | 82 | B | |

| 11 | UX3110 | UX-d110-C-C16-H80-L133 | 16 | 27 | 52 | 80 | 133 | 53 | 13.6 | 93 | UX0006 M3×0.35×10C |

C |

| 12 | UX3120 | UX-d120-C-C16-H80-L133 | 16 | 27.3 | 52 | 80 | 133 | 53 | 13.6 | 103 | C | |

| 13 | UX3130 | UX-d130-C-C16-H80-L133 | 16 | 28 | 52 | 80 | 133 | 53 | 13.6 | 115 | C | |

| 14 | UX4140 | UX-d140-D-C20-H105-L158 | 20 | 32.5 | 72.5 | 105 | 158 | 53 | 15.3 | 160 | UX0007 M3×0.35×13D |

D |

| 15 | UX4150 | UX-d150-D-C20-H105-L158 | 20 | 32.5 | 72.5 | 105 | 158 | 53 | 15.3 | 178 | D | |

| 16 | UX4160 | UX-d160-D-C20-H105-L158 | 20 | 32.5 | 72.5 | 105 | 158 | 53 | 15.3 | 196 | D | 17 | UX7200 | UX-d200-G-C25-H120-L175 | 20 | 38.5 | 76.5 | 115 | 170 | 55 | 18 | 231 | UX0008 M3x0.35x16E |

E |

| 18 | UX7200 | UX-d200-G-C25-H120-L175 | 20 | 38.5 | 76.5 | 115 | 170 | 55 | 18 | 254 | E | |

| 19 | UX7200 | UX-d200-G-C25-H120-L175 | 20 | 38.5 | 76.5 | 115 | 170 | 55 | 18 | 278 | E | |

| 20 | UX7200 | UX-d200-G-C25-H120-L175 | 25 | 43.5 | 76.5 | 120 | 175 | 55 | 20 | 344 | UX0009 M4x0.5x19F |

F |

| 21 | UX7210 | UX-d210-G-C25-H120-L175 | 25 | 43.5 | 76.5 | 120 | 175 | 55 | 20 | 373 | F | |

| 22 | UX7220 | UX-d220-G-C25-H120-L175 | 25 | 43.5 | 76.5 | 120 | 175 | 55 | 20 | 403 | F | |

| 23 | UX7230 | UX-d230-G-C25-H120-L175 | 25 | 48 | 72 | 120 | 175 | 55 | 22 | 427 | UX0010 M4x0.5x21G |

G |

| 24 | UX7240 | UX-d240-G-C25-H120-L175 | 25 | 48 | 72 | 120 | 175 | 55 | 22 | 445 | G | |

| 25 | UX7250 | UX-d250-G-C25-H120-L175 | 25 | 48 | 72 | 120 | 175 | 55 | 22 | 492 | G |

(1) The LTB parameter varies between USPOT and UCHAMF inserts

(2)The achieved tolerance for the counterbore or spotface diameter (ØD) is ±0.1 mm (0.004″)

(3) The insert series must match the series of the tool holder.

Note: Tool-holders and inserts are sold separately.

.png)

LTB1 – Length To Bottom / RFC – Relief For Cutting / FL – Folding Length

| Ødmin. Pilot Hole |

Tool- Holder SKU |

Tool-Holder Description |

ØDS h6 | FL | RFC | H | L | L1 | LTB1 (1) USPOT |

ØDmax (2) | Weight (lBs) |

Insert Clamping Screw M*P*L (mm) |

Series(2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.315 | UX2080 | UX-d080-B-C16-H62-L115 | 0.630 | 0.669 | 1.693 | 2.441 | 4.528 | 2.087 | 0.268 | 0.728 | 0.1521 | UX0005 M2.5×0.35x7B |

B |

| 0.354 | UX2090 | UX-d090-B-C16-H62-L115 | 0.630 | 0.701 | 1.693 | 2.441 | 4.528 | 2.087 | 0.268 | 0.827 | 0.1676 | B | |

| 0.394 | UX2100 | UX-d090-B-C16-H62-L115 | 0.630 | 0.740 | 1.693 | 2.441 | 4.528 | 2.087 | 0.268 | 0.906 | 0.1808 | B | |

| 0.433 | UX3110 | UX-d110-C-C16-H80-L133 | 0.630 | 1.063 | 2.047 | 3.150 | 5.236 | 2.087 | 0.449 | 1.024 | 0.205 | UX0006 M3x0.35x10C |

C |

| 0.472 | UX3120 | UX-d110-C-C16-H80-L133 | 0.630 | 1.075 | 2.047 | 3.150 | 5.236 | 2.087 | 0.449 | 1.102 | 0.2271 | C | |

| 0.512 | UX3130 | UX-d110-C-C16-H80-L133 | 0.630 | 1.102 | 2.047 | 3.150 | 5.236 | 2.087 | 0.449 | 1.181 | 0.2535 | C | |

| 0.551 | UX4140 | UX-d140-D-C20-H105-L158 | 0.787 | 1.280 | 2.854 | 4.134 | 6.220 | 2.087 | 0.531 | 1.280 | 0.3527 | UX0007 M3x0.35x13D |

D |

| 0.591 | UX4150 | UX-d150-D-C20-H105-L158 | 0.787 | 1.280 | 2.854 | 4.134 | 6.220 | 2.087 | 0.531 | 1.358 | 0.3924 | D | |

| 0.630 | UX4160 | UX-d140-D-C20-H105-L158 | 0.787 | 1.280 | 2.854 | 4.134 | 6.220 | 2.087 | 0.531 | 1.457 | 0.4321 | D | |

| 0.669 | UX4170 | UX-d170-E-C20-H115-L170 | 0.787 | 1.516 | 3.012 | 4.528 | 6.693 | 2.165 | 0.630 | 1.555 | 0.5093 | UX0008 M3x0.35x16E |

E |

| 0.709 | UX4180 | UX-d180-E-C20-H115-L170 | 0.787 | 1.516 | 3.012 | 4.528 | 6.693 | 2.165 | 0.630 | 1.634 | 0.56 | E | |

| 0.748 | UX4190 | UX-d190-E-C20-H115-L170 | 0.787 | 1.516 | 3.012 | 4.528 | 6.693 | 2.165 | 0.630 | 1.732 | 0.6129 | E | |

| 0.669 | UX4200 | UX-d200-F-C25-H120-L175 | 0.984 | 1.713 | 3.012 | 4.724 | 6.890 | 2.165 | 0.701 | 1.811 | 0.7584 | UX0009 M4x0.5x19F |

F |

| 0.827 | UX4210 | UX-d210-F-C25-H120-L175 | 0.984 | 1.713 | 3.012 | 4.724 | 6.890 | 2.165 | 0.701 | 1.909 | 0.8223 | F | |

| 0.866 | UX6220 | UX-d220-F-C25-H120-L175 | 0.984 | 1.713 | 3.012 | 4.724 | 6.890 | 2.165 | 0.701 | 1.988 | 0.8885 | F | |

| 0.906 | UX4230 | UX-d230-F-C25-H120-L175 | 0.984 | 1.890 | 2.835 | 4.724 | 6.890 | 2.165 | 0.787 | 2.087 | 0.9414 | UX0010 M4x0.5x21G |

G |

| 0.945 | UX4240 | UX-d240-F-C25-H120-L175 | 0.984 | 1.890 | 2.835 | 4.724 | 6.890 | 2.165 | 0.787 | 2.185 | 0.9811 | G | |

| 0.984 | UX4250 | UX-d250-F-C25-H120-L175 | 0.984 | 1.890 | 2.835 | 4.724 | 6.890 | 2.165 | 0.787 | 2.264 | 1.0847 | G |

(1) The LTB parameter varies between USPOT and UCHAMF inserts

(2)The achieved tolerance for the counterbore or spotface diameter (ØD) is ±0.1 mm (0.004″)

(3) The insert series must match the series of the tool holder.

Note: Tool-holders and inserts are sold separately.

.png)

We can also modify or produce tailor-made tool-holders.

If you need further assistance, please don’t hesitate to contact us.

Providing an application drawing or sketch, the raw material details, and any other relevant information will help us assist you more effectively.

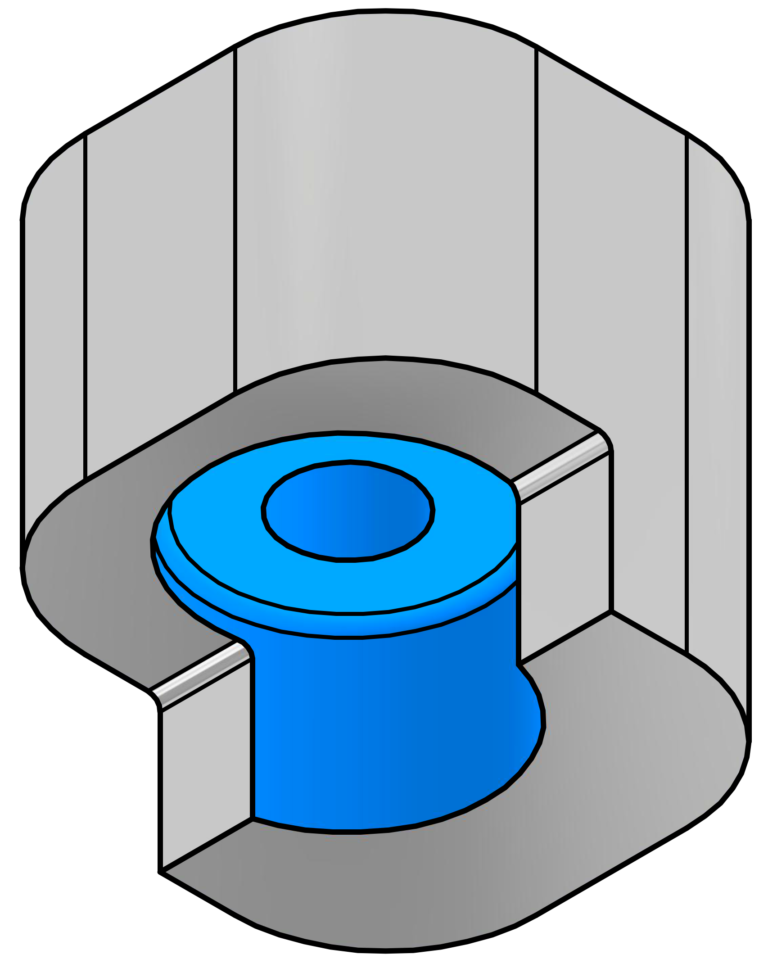

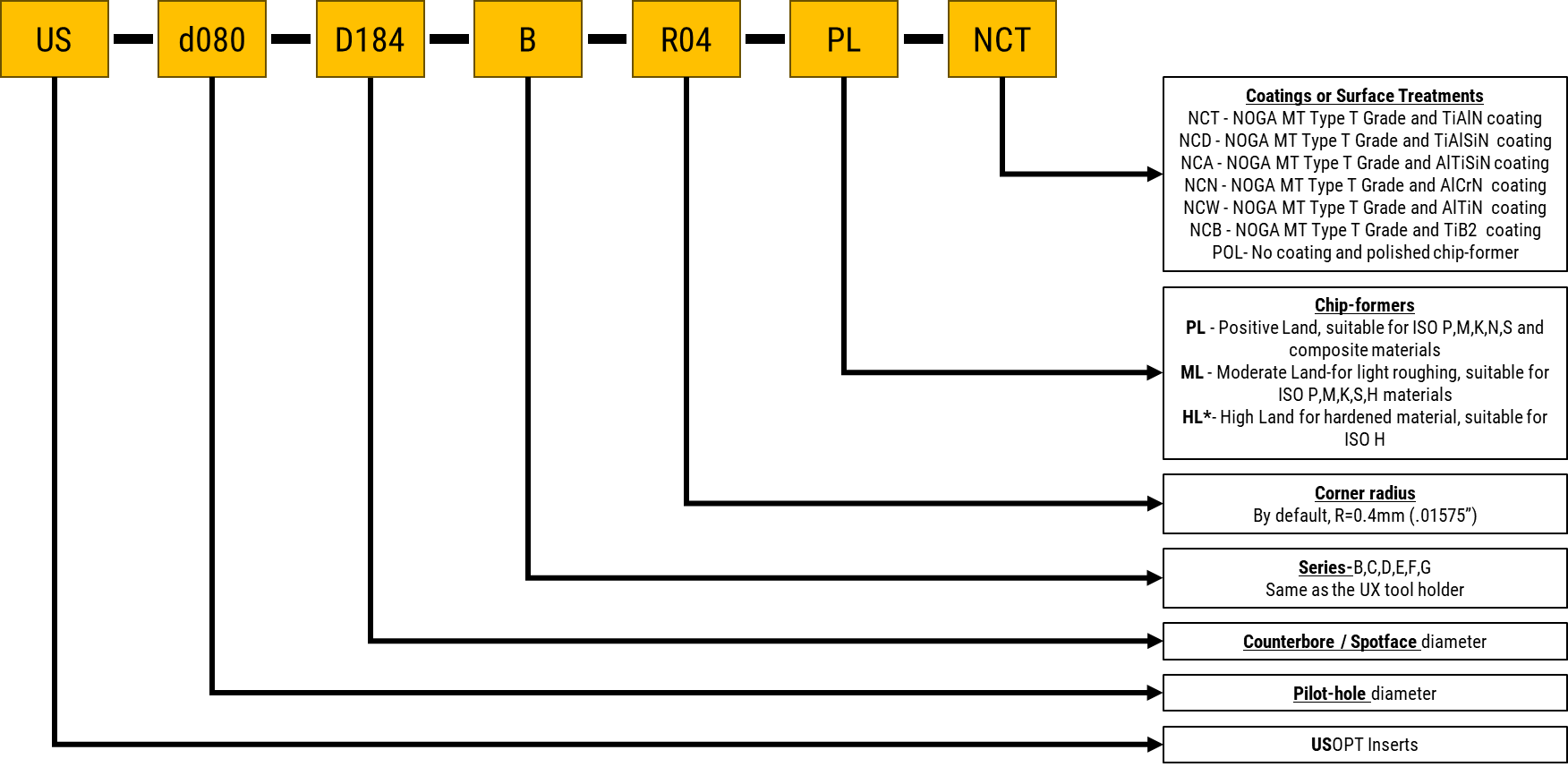

The USPOT inserts are available as semi-standard solutions tailored to customer applications.

The recommended tool-holder is: UX2080 / UX-d080-B-C16-H62-L115 with Ødmin=8mm (0.315")

The corresponding insert is: US-d087-D176-B-R02-ML-NCT

Ensure that the pilot-hole length (L) is less than or equal to the RFC (Relief For Cutting) L⩽RFC ,as specified in the UBACK tool-holders table below.

If you need further assistance, please don’t hesitate to

contact us.

Providing an application drawing or sketch, the raw material specifications,

and any other relevant information will help us assist you more effectively.

| Coating | Key Features | Applications | Industries | Material Examples | ISO GROUP | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| P | M | K | N | S | H | |||||

| TiAlN | Suitable for mild steels, cast iron, stainless steel, titanium alloys, Inconel, tool steel, and hardened steels. Offers excellent thermal stability, oxidation resistance, and wear resistance. | Ideal for high-speed cutting and general-purpose machining. Performs well in both wet and dry conditions. | Aerospace, Automotive, General Engineering | AISI 304, 42CrMo4, GG (Grey Cast Iron), Ti6Al4V | ✓ | ✓ | ✓ | X | X | ✓ |

| TiAlSiN | Provides exceptional hardness and oxidation resistance, withstanding temperatures above 1,200°C. Suitable for high-strength steels, superalloys, hardened steels (over 45 Rc), and titanium alloys. | Best for high-performance machining in demanding environments. Excels in dry machining at high speeds. | Aerospace, Automotive, Die and Mold | Inconel 718, AISI 4140, Ti6Al4V | ✓ | ✓ | X | X | X | X |

| AlTiSiN | Offers high hardness, thermal stability, and resistance to wear and oxidation. Suitable for stainless steel, hardened cast, superalloys, and steels over 45 Rc. | Designed for high-speed machining in extreme conditions. Performs exceptionally in dry machining. | Aerospace, Automotive, Precision Engineering | AISI 316, AISI H13, Hastelloy | X | ✓ | X | X | ✓ | X |

| AlCrN | Provides excellent oxidation resistance (up to 1,100°C), toughness, and abrasion resistance. Suitable for carbon steels, cast iron, stainless steel, and aluminum. | Suitable for general machining in wet and dry environments. Excels in abrasive and high-wear applications. | Automotive, Aerospace, Die and Mold | AISI 304, AISI 1045, GG, AL6061 | ✓ | ✓ | X | X | X | X |

| AlTiN | High hardness, wear resistance, and thermal stability up to 1,100°C. Designed for mild steels, cast iron, high-speed steels, tool steel, and hardened materials. | Ideal for heavy-duty machining and high-speed cutting. Performs well in dry and abrasive conditions. | Aerospace, Automotive, Heavy Engineering | AISI 4340, M2 HSS, GG (Grey Cast Iron) | ✓ | ✓ | X | X | X | X |

| TiB2 | Known for exceptional chemical stability, low friction, and high thermal conductivity. Best for machining non-ferrous materials such as aluminum, copper, brass, and magnesium alloys. Reduces friction and Built-Up Edge (BUE). | Optimized for high-speed machining of non-ferrous metals. Prevents material adhesion and improves efficiency. | Aerospace, Automotive, Electronics | AL7075, 6061-T6, Copper, Magnesium Alloys (AZ31) | X | X | X | ✓ | ✓ | X |

| Polishing | Provides a smooth, refined surface finish by removing micro-defects, scratches, or burrs. Enhances aesthetics and surface quality. Reduces friction and BUE. | Suitable for machining aluminum with high speeds and high MRR (Metal Removal Rates) | Aerospace, Automotive | AL7075, 6061-T6, Copper, Magnesium Alloys (AZ31) | X | X | X | ✓ | X | X |

Suitable for all around purpose and ISO P,M,K,N,S as well as composite materials